Products & Services

- • Bus duct products & Services

- • Switchgear Products

- • Disconnect Switch

- • Crown-sulator ®

- • Joule-ious 105

- • Field Services

Installation & Field Services

With an eye on America's growing energy needs, Crown Electric Eng & Mfg believes that our Nation can only continue to succeed and lead the world if we possess a sufficient, rock solid electrical supply and transmission infrastructure.

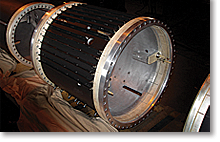

Crown Electric engineers, designs, fabricates, installs, services and maintains Iso Phase Bus (IPB). Crown's IPB is engineered and fabricated to provide the highest level of reliability when transporting medium voltage bulk power.

Our product line's design and fabrication capability for new IPB installations extends to 30,000 amps at voltage classes requiring up to 200kV BIL. Crown's present capabilities for on site maintenance extends to voltage and current ratings even higher for both continuous and non-continuous IPB designs of all major US domestic legacy designs.

Service and flexibility add a level of customer satisfaction that exceeds the mere expectation of a properly designed and manufactured product. We want you to Specify Crown and we work to achieve levels of QA/QC and service support so that your company will want to specify Crown as well.

Crown Electric maintains, services and builds match and line connections to all domestic legacy IPB and Bus Duct. If you're installing a new Tap for an Auxiliary transformer, upgrading your IPB run's current carrying capabilities, correcting for years of IPB enclosure corrosion, replacing poor joints, or changing out a GSU (Generator Step-Up Unit) transformer; Crown will make it happen quickly, efficiently and professionally.

Let The Power Flow

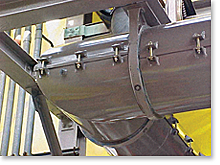

Iso Phase Bus (IPB) and Bus Duct are the arteries that carry the flow of bulk power to the Systems that bring life to your facility. These conduits of electrical power go about doing their jobs quietly and efficiently.

But all too often they become neglected due to the belief that they are static devices needing no maintenance or care. Age, vibration, thermal cycling, overheating, and material failures, coupled with environmental factors such as smoke, dirt and salts can all ravage a plant's bus. Slowly loosening hardware

due to thermal cycling, critter encroachment, bellows drying and cracking,

gaskets aging and housing joints separating and leaking can all lead to violent,

catastrophic failures.

Is preventative maintenance a good idea?

You bet! But preventative maintenance on Iso Phase Bus (IPB) and Bus Duct should only be done by highly experienced, well trained, and properly equipped personnel like the men and women of Crown Electric Engineering and Manufacturing LLC.

When Crown Electric arrives onsite, it trailers a full fabrication shop supported by some of the industry's best trained IPB & bus duct maintenance personnel. Our team is supported by a new 50,000+ square foot manufacturing facility located on 6.5 acres in Middletown Ohio. Crown's facility hosts a full line up of CNC punch presses, shears, press brakes, custom tooling and state of the art welding equipment to ensure any problems that arise in the field can be immediately addressed at the factory and then couriered back to our onsite personnel for the quickest possible correction.

Crown stocks all common sizes of copper, aluminum and sheet metal material for immediate turn around.

Crown's commitment to inventory drastically limits any down time caused by unexpected occurrences found during routine inspection and maintenance. This commitment can be a life saver when a facility is experiencing an unscheduled outage. Prior to beginning any onsite work, Crown Electric can carefully survey your equipment to insure proper and sufficient materials needed to cover any eventualities before commencement of any maintenance disassembly.

Opening IPB or a bus duct section for cleaning and having a custom support-insulator fall out cracked could likely have a huge adverse impact on the scheduled return to service date.

A dried, cracked bellows needing replacement without an available on hand spare could keep equipment off line for weeks.

These types of concerns evaporate when you have Crown Electric Engineering & Manufacturing as your on site IPB and bus duct partner!

Maintenance

Consider these questions:

• Are your joints taped or booted?

• Are the quantities, sizes and shapes already procured and now on hand?

• Does the work require a fire watch?

• Will the bus duct covers need new gasketing?

• Is sufficient replacement hardware available?

• Do you know the correct hardware grade and finish?

• Should the hardware be non-magnetic?

• Do the connection joints need re-silvering?

• Do you have sufficient replacement conductor material if any lengths need replacing?

• Do you need to replace any flex braids?

• Will fabrication or welding be required?

• What are the bracing requirements?

• Do you have a plan in place to handle insulator failures?

This specialized work is best done by repeatedly experienced personnel with

up to date certifications.

Upgrades

Upgrades may be as simple as changing out old gasketing and flex braids, or they might be as voluminous as the complete replacement of the entire IPB runs corroded enclosures. Is recurring maintenance on an older forced cooled system forcing you to change your IPB to a passive radiant design? Are the old externally mounted enclosure shunt braids looking as though they will not be able to properly perform their function under fault conditions?

Is your facility planning to up-rate the generators and need more ampacity

on the IPB?

Crown Electric can add forced cooling and heat exchangers to re-rate your IPB to match the new generator capabilities. Crown Electric can help your facility service, test, maintain, upgrade and up-rate virtually any domestic manufacturer's legacy Iso Phase Bus.

Engineering, Design, Fabrication

Crown Electric brings the same expertise and capabilities to

your IPB's maintenance that we provide for the supply of all

our new IPB installations.

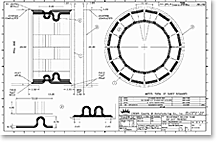

IPB calculations, engineering and environmental considerations, longevity requirements and future maintenance considerations are all factors that Crown Electric Engineering and Manufacturing LLC can help you weigh when your company is venturing out to make decisions on IPB.

GSU Change Outs

Generator Step-Up (GSU) Transformers and Auxiliary transformers generally provide decades of trouble free service. On occasion, whether scheduled or not, GSU units may need to be replaced. Quite often this means new IPB low voltage bushing enclosures (throat box), high amperage IPB connections to the new low voltage bushings, new short runs of IPB, anti-vibration connections and possible structural modifications. Depending on the IPB design, new de-ionizing baffles and associated cross over plenums may also be required. Iso Phase Bus modifications for GSU change outs is a Crown specialty. Our shop capabilities, material stock, flexible manufacturing and on site engineering services makes Crown the partner of choice for any GSU or Auxiliary Transformer replacement.

Engineering and Field Services

Crown Electric Engineering and Manufacturing LLC has an experienced team of engineering, supervision and skilled craftsmen who can bring our mobile on-site service facility to your site any where in the continental US. Whether we are installing or servicing our own IPB or that produced by others, Crown Electric will support every aspect of your facilities IPB and Bus Duct outage needs.